Prosim powered by Duratt

Since 1993

Duratt®: Pioneering linear motor technology in dynamic mechanical testing

Founded in Shanghai in 2015 by a team of professional engineers specialising in mechanical and electronic design, software development, and application engineering, Duratt® is the first company in China to introduce linear motor technology into dynamic mechanical testing systems.

Duratt® provides advanced and customised test instrument solutions for dynamic mechanical characterisation of materials and components used in aerospace, automotive, electronic, and biomedical applications. Duratt® core technology lies in the independently developed high-performance linear motor and control system, which ensures exceptional dynamic frequency response, large displacement capability, high precision, and long-term operational stability.

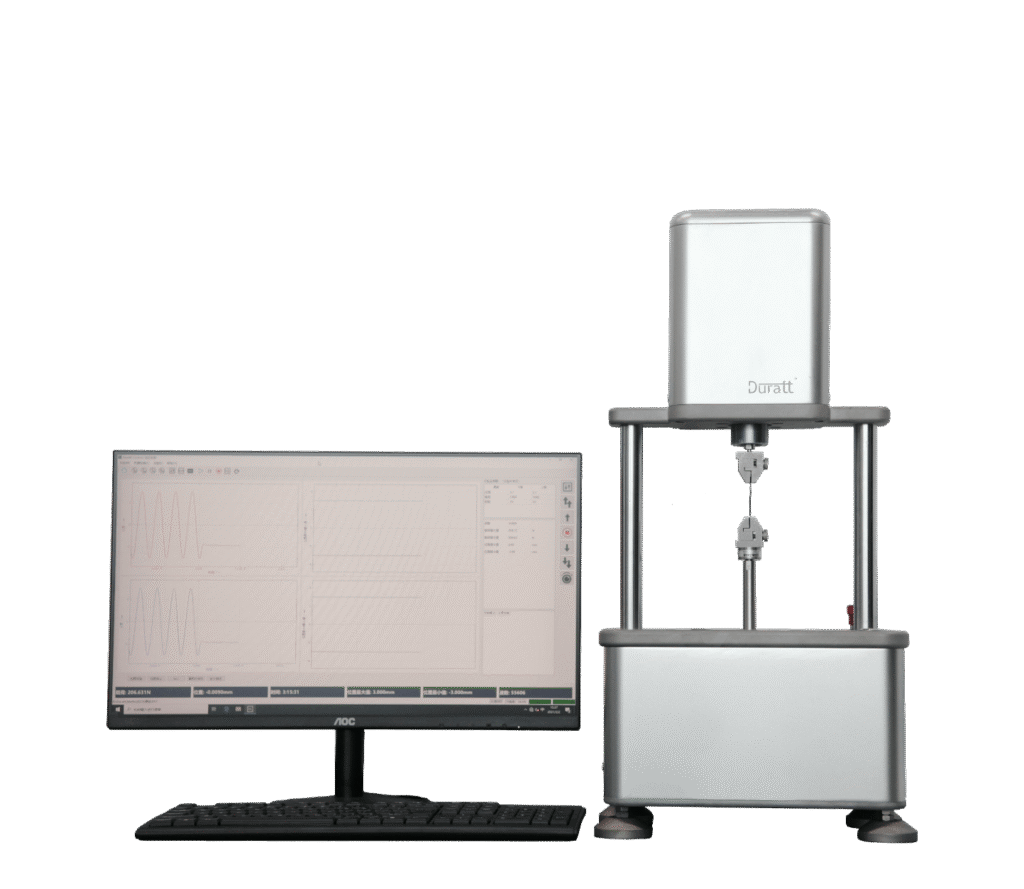

Duratt® TT series testing machines utilise high-performance linear motors and control systems with proprietary intellectual property rights, enabling the simultaneous realization of high performance, high frequency, high precision, and high durability in a single machine.

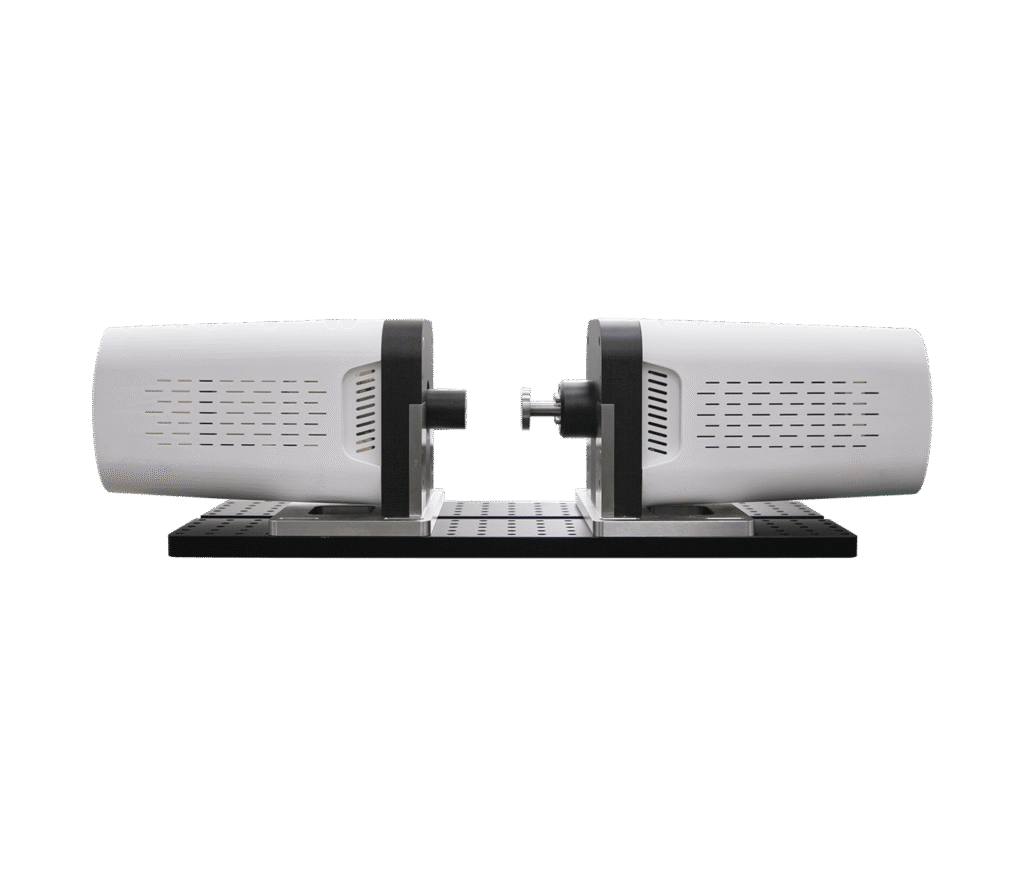

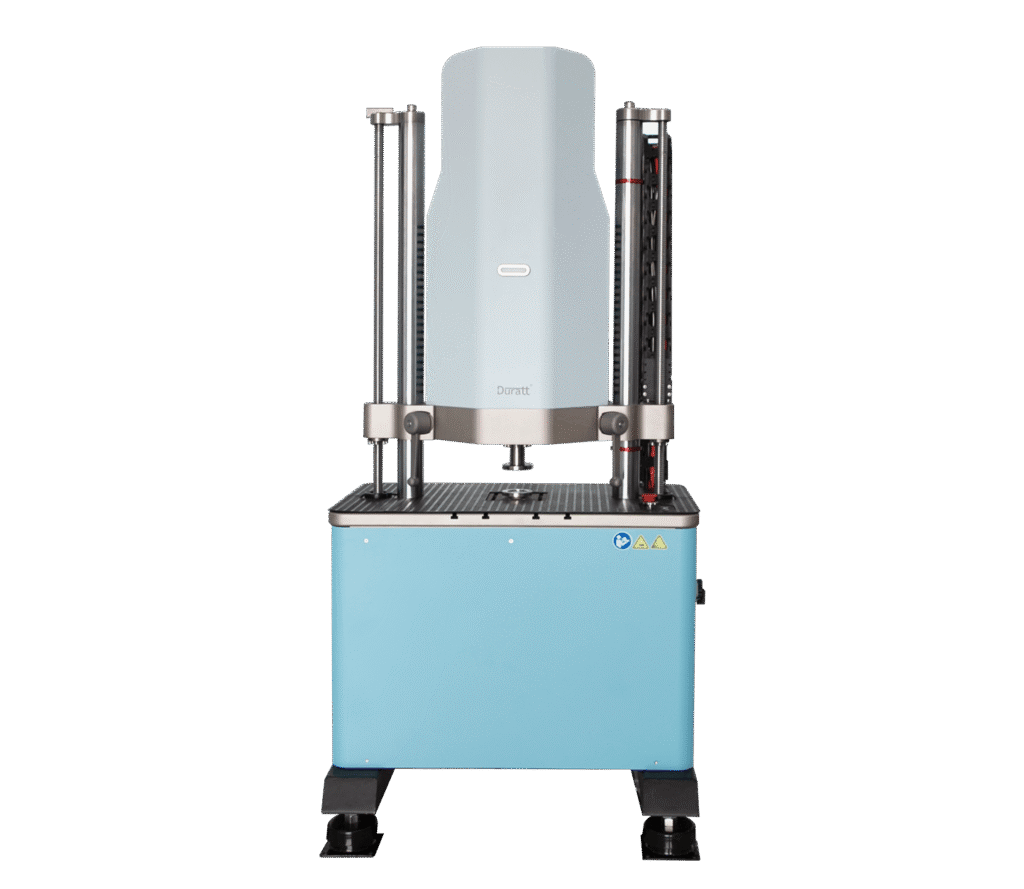

The Duratt® D50 benchtop test platform integrates a customized high-performance linear motor and control system, enabling high-frequency dynamic excitation from static to 100 Hz, with a dynamic load of 50 N and a dynamic displacement of up to 11 mm. Its compact size makes it widely applicable to dynamic mechanical property testing of various flexible materials and small components, as well as high-performance static tension and compression testing.

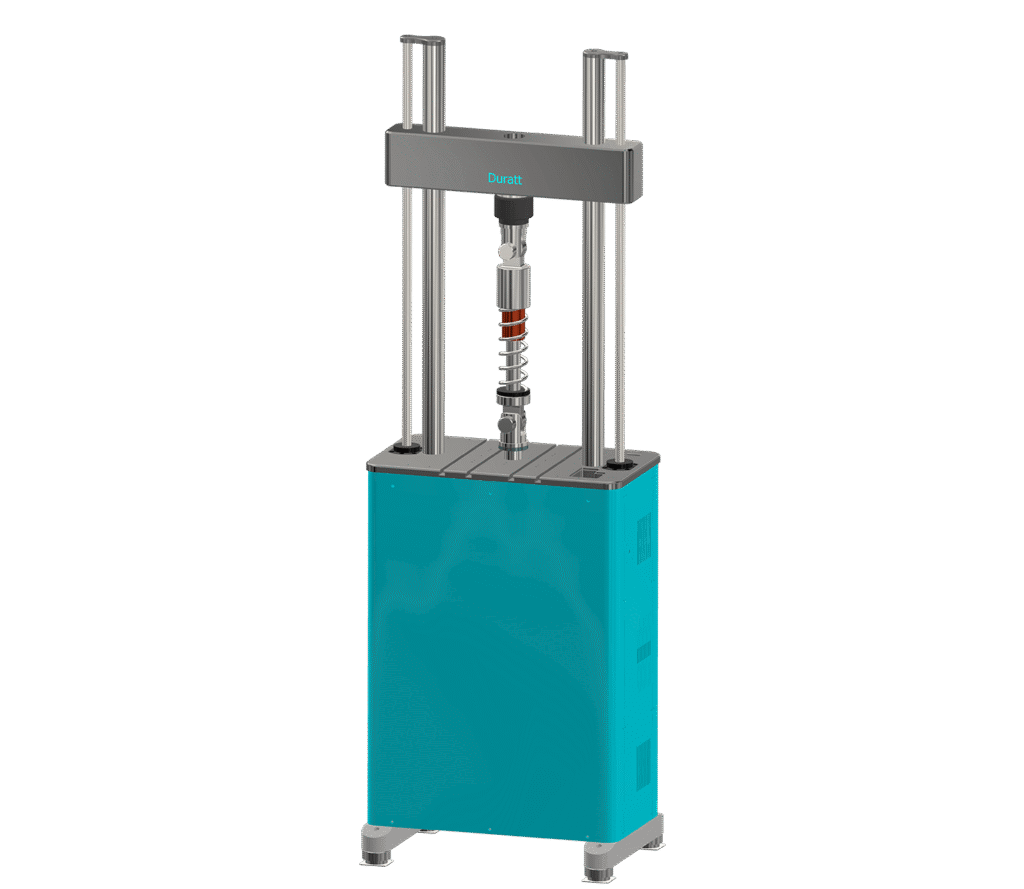

The Duratt® D800 dynamic testing platform integrates customized high-performance linear motors and control systems, enabling high-frequency dynamic excitation from static to 200 Hz, with a dynamic load of 800 N and a dynamic displacement of up to 41 mm. It is widely applicable to dynamic mechanical property testing of various materials and small components, as well as high-performance static tension and compression testing.

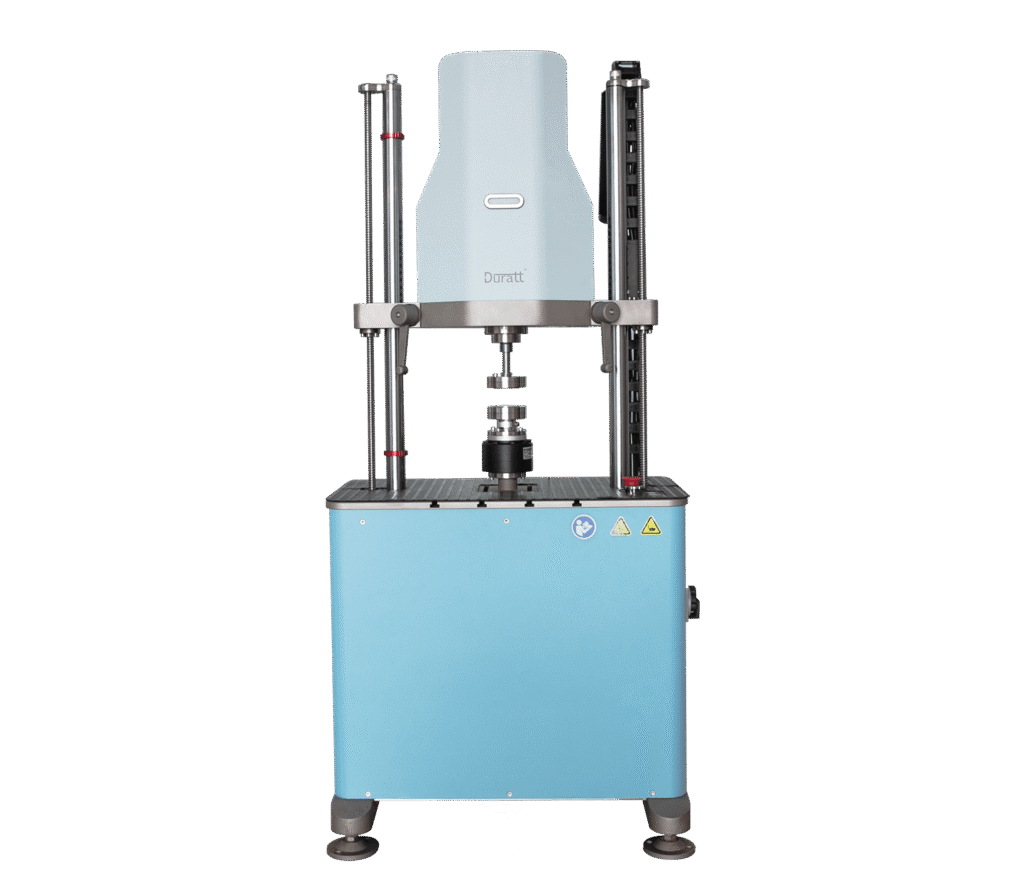

The Duratt® D2000 dynamic testing platform integrates customized high-performance linear motors and control systems, enabling high-frequency dynamic excitation from static to 200Hz, with a dynamic load of 2000N and a dynamic displacement of up to 65mm. It is widely applicable to dynamic mechanical property testing of various materials and small components, as well as high-performance static tension and compression testing.

The Duratt® D4000 dynamic testing platform integrates customized high-performance linear motors and control systems, enabling high-frequency dynamic excitation from static to 200 Hz, with a dynamic load of 4200 N and a dynamic displacement of up to 65 mm. It is widely applicable to dynamic mechanical property testing of various materials and small components, as well as high-performance static tension and compression testing.

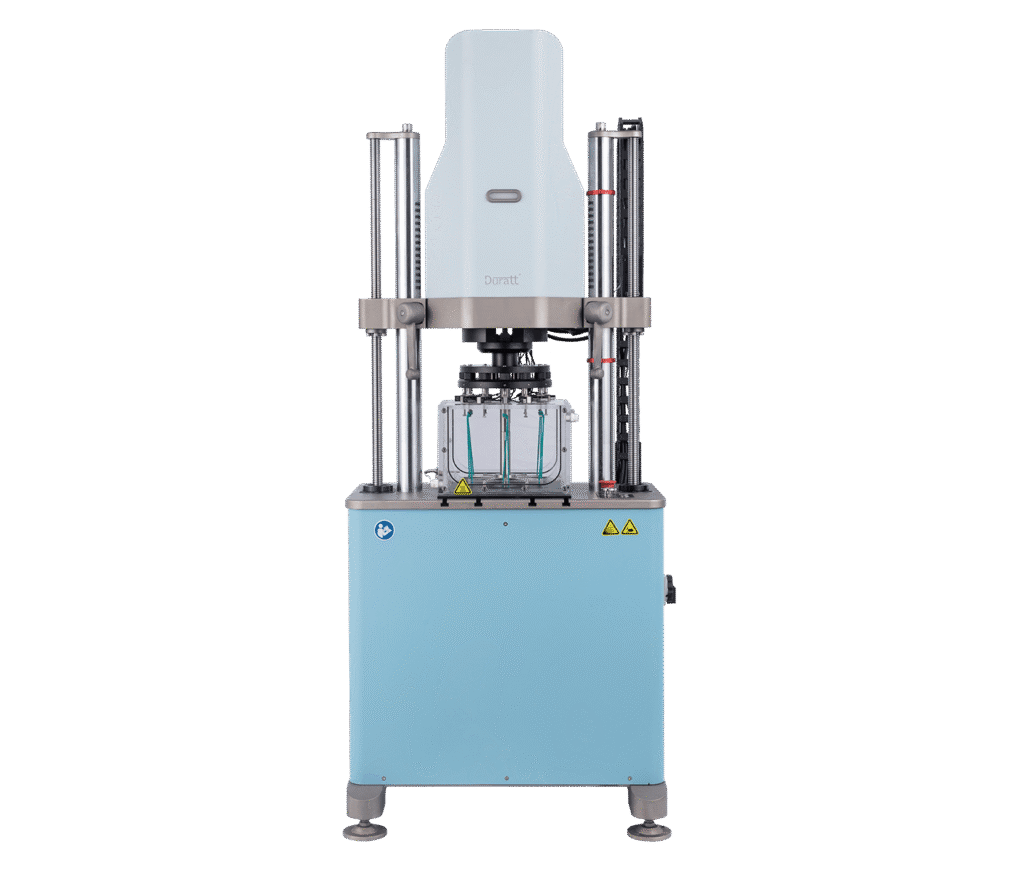

The Duratt® D8000 high-load dynamic test platform integrates a customized, high-performance, high-power linear motor and control system. It can achieve high-frequency dynamic excitation from static to 200Hz, with a maximum dynamic load of 8200N and a maximum dynamic displacement of 65mm. It is widely applicable to dynamic mechanical property testing of various materials, components or products, as well as high-performance static tension and compression testing.

The Duratt® D20000 high-load dynamic test platform integrates a customized, high-performance, high-power linear motor and control system. It can achieve high-frequency dynamic excitation from static to 200Hz, with a maximum dynamic load of 18,000N and a maximum dynamic displacement of 80mm. It is widely applicable to dynamic mechanical property testing of various materials, components, or products, as well as high-performance static tension and compression testing.

Contact us.

If you have any specific requirements not fully addressed by the above, please do not hesitate to contact us.

We are always happy to look at the customisation of existing equipment or design and build projects to a customer’s specifications.